Construction Management, Inspection and Testing, Geotechnical Project Auscultation with sensors (Data Tunnel) with BIM for the new L-9 line of the Barcelona Metro.

General information:

Date (year): 2020 – ongoing

Client: Infraestructures.cat

Location: Barcelona (Spain)

Photography property: ©SOCOTEC Spain, GISA S.A.U

SOCOTEC is leading a visionary project: the construction of the new L-9 line of the Metro, the longest in Europe. At 47.8 km, including 43.7 km underground, it represents a monumental breakthrough in underground engineering. This tender has been acquired thanks to our experience in Infrastructure Construction Management and we collaborated with TPF, Getinsa, Euroestudios and Tunelconsult to shape this innovative transport network.

Talk to our experts

Services Provided:

SOCOTEC, supported by its strategic partners, meticulously defines the design and detailed planning of the initial section of the L-9 of the Barcelona Metro. Our highly trained team oversees every phase of the project, ensuring flawless and on-time execution. In addition, detailed inspections and rigorous tests are carried out at facilities, stations and evacuation shafts to ensure quality and safety in each component. BIM technology and Tunel Data sensors provide a real-time view of the status and behavior of underground infrastructure.

Main Services:

- Construction project (studies and designs) of the first section of the L-9 of the Metro

- Management of the execution works

- Inspection and testing of installations, stations and evacuation shafts

- Geotechnical Project and Geological Profiles of the Tunnel

- Auscultation with sensors (Data Tunnel ) with BIM

Tunnel Boring Machine

Advances and Challenges from SOCOTEC's Technical Perspective

This tunnel boring machine represents a giant step towards a more efficient and sustainable infrastructure for Barcelona. It is a milestone in the history of engineering, consolidating SOCOTEC as the only company capable of leading the Construction Management of this project, guaranteeing its prosperity and safety at every stage.

The design of the tunnel has been conceived after exhaustive geotechnical and auscultation tests. The implementation of a tunnel boring machine in the final section ensures safety in changing conditions at depths of between 35 and 70 metres. This innovative approach places SOCOTEC at the forefront of tunnel engineering.

This tunnel boring machine represents a giant step towards a more efficient and sustainable infrastructure for Barcelona. It is a milestone in the history of engineering, consolidating SOCOTEC as the only company capable of leading the Construction Management of this project, guaranteeing its prosperity and safety at every stage.

The design of the tunnel has been conceived after exhaustive geotechnical and auscultation tests. The implementation of a tunnel boring machine in the final section ensures safety in changing conditions at depths of between 35 and 70 metres. This innovative approach places SOCOTEC at the forefront of tunnel engineering.

Innovation for the Control and Safety of Underground Infrastructures:

The combination of BIM and advanced sensor systems (Tunnel Data) sets a new standard in control and safety of underground infrastructures. SOCOTEC is at the forefront of tunnel engineering by implementing a tunnel boring machine in the final section, ensuring safety at depths between 35 and 70 meters.

Monitoring and Geotechnics

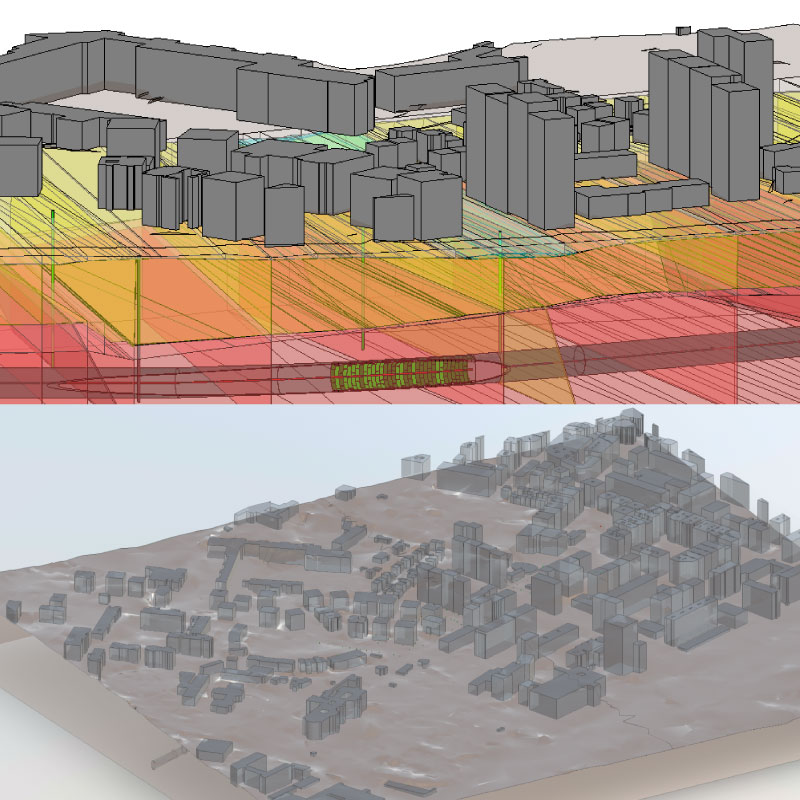

Digitalization for safety and viability

SOCOTEC adopts current digitalization methodologies and implements BIM to ensure the rigor and control of information, meeting deadlines and achieving the optimization of public costs.

Inspections have been carried out in areas of influence through which the TBM would pass to ensure its passage. To this end, SOCOTEC has installed more than 2900 points with automatic and manual readings that allow total monitoring.

SOCOTEC adopts current digitalization methodologies and implements BIM to ensure the rigor and control of information, meeting deadlines and achieving the optimization of public costs.

Inspections have been carried out in areas of influence through which the TBM would pass to ensure its passage. To this end, SOCOTEC has installed more than 2900 points with automatic and manual readings that allow total monitoring.

Types of stations:

Designed based on the technical needs of each section

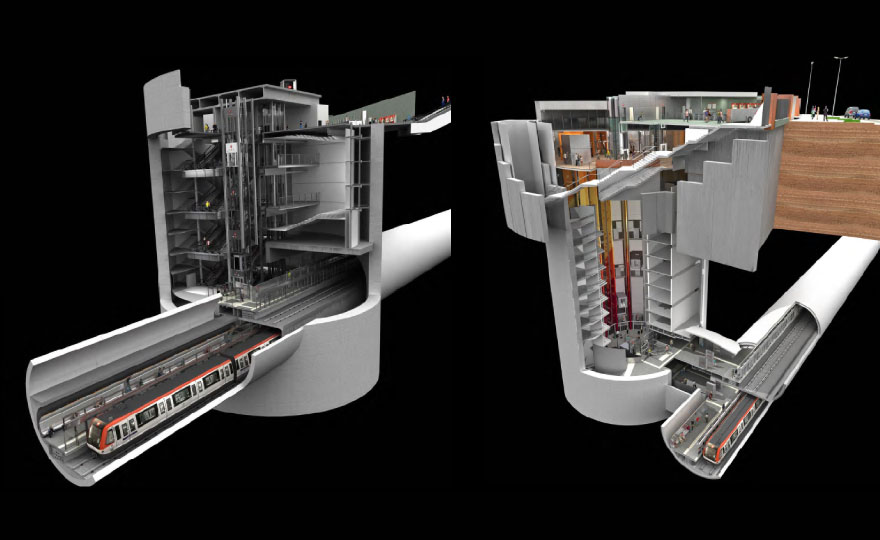

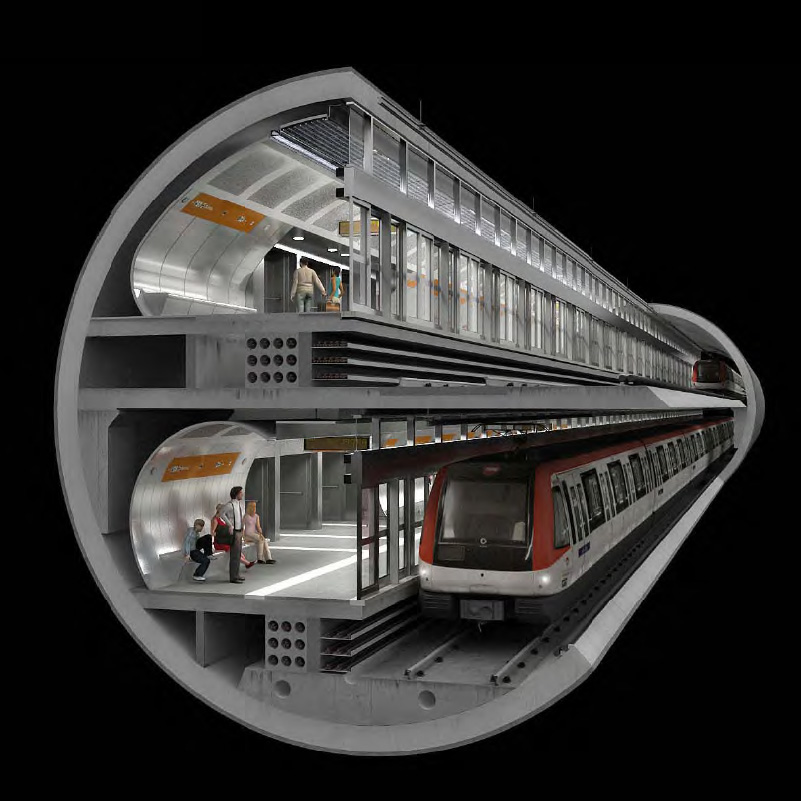

- Double-Height Tunnels: Offer optimal transport capacity by accommodating convoys on two levels.

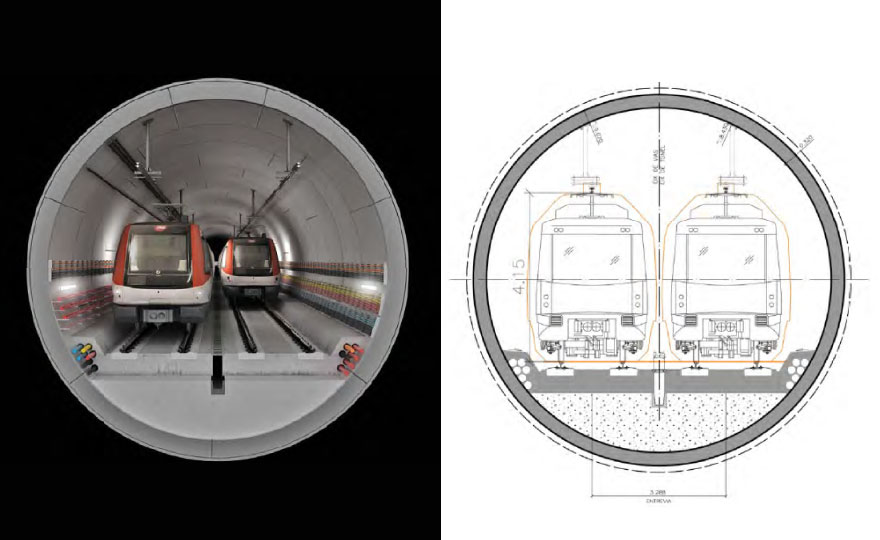

- 9.4m Diameter Tunnels: Designed for parallel train circulation, they maximize operational efficiency.

- Mine Tunnel: A unique solution with a half-arch tunnel and a narrow lower mine.

- Viaduct: Elevates tracks to 6 meters off the ground, facilitating efficient two-way traffic flow.

- Double-Height Tunnels: Offer optimal transport capacity by accommodating convoys on two levels.

- 9.4m Diameter Tunnels: Designed for parallel train circulation, they maximize operational efficiency.

- Mine Tunnel: A unique solution with a half-arch tunnel and a narrow lower mine.

- Viaduct: Elevates tracks to 6 meters off the ground, facilitating efficient two-way traffic flow.

Types of Route:

Adaptation to technical needs

- Double-Height Tunnels: Offer optimal transport capacity by accommodating convoys on two levels.

- 9.4m Diameter Tunnels: Designed for parallel train circulation, they maximize operational efficiency.

- Mine Tunnel: A unique solution with a half-arch tunnel and a narrow lower mine.

- Viaduct: Elevates tracks to 6 meters off the ground, facilitating efficient two-way traffic flow.

- Double-Height Tunnels: Offer optimal transport capacity by accommodating convoys on two levels.

- 9.4m Diameter Tunnels: Designed for parallel train circulation, they maximize operational efficiency.

- Mine Tunnel: A unique solution with a half-arch tunnel and a narrow lower mine.

- Viaduct: Elevates tracks to 6 meters off the ground, facilitating efficient two-way traffic flow.

Infrastructure Construction Management:

In this complex project, Infrastructure Site Management is at the core of our approach. We guarantee acoustic protection, controlling and mitigating vibrations, dust emissions and protecting the surrounding vegetation. In addition, we manage the water environment and waste responsibly, contributing to the sustainability of the project and leaving a lasting legacy in the city of Barcelona. Our experience in infrastructure construction management allows us to approach this project with the excellence and precision that a project of this magnitude deserves.